Conduits protect electrical wiring, but only if you limit the number of wires in the conduit to the appropriate amount. Crowding the conduit is a bad idea. First of all, you are more likely to damage the conductors while pulling them through the tubing. Secondly, the heat build-up will harm the wires in the long run. This is why the fill capacity is so important. The term refers to the maximum number of wires a conduit can handle.

AWG Vs Number of Wires In 3/4 Conduit

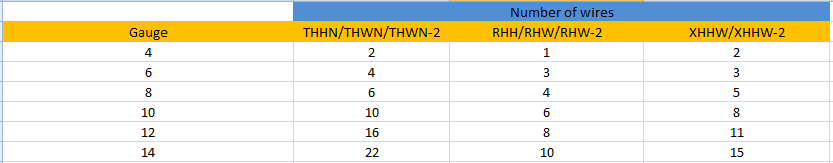

According to NEC’s rule, ¾ EMT can accommodate 22 14AWG wires, 9 12/2 AWG wires, 16 12 AWG wires, 10 10 AWG wires, 6 8 AWG wires, 4 6 AWG wires, and 2 4 AWG THHN/THWN wires

How To Calculate The Number Of 4, 6, 8, 10, 12, 12/2, 14, 14/2, 16, 18 Gauge Wires That Fit In ¾ Conduits?

Calculating the fill capacity for a particular wire size involves the following:

1). Wire Type

The gauge is not enough. You should identify the wire type. Essentra Components have published a table showing the different types of cables and their attributes. For instance, THHW has no outer covering. It is available in ratings of 167 degrees F (Wet Locations) and 90 degrees C (Dry Locations). You find it in feeders, service entrances, and branch circuits.

THHN is rated for 194 degrees F (Dry and Damp Locations). You find it in machine tools and control circuits.

2). Conduit Material

What is the conduit made of? Like the wire type, the material will shape the application. For instance, PVC-coated metal conduits are popular in factory wires and connections.

3). Find an NEC table that shows wires and conduits

These tables will reveal the various wire sizes, wire types, and their corresponding conduit types and sizes.

To find the fill capacity, find the cell where the wire and conduit sizes intersect. For instance, if you want to determine the number of 8AWG lines a ¾ conduit can accommodate, find the column with ‘8AWG.’

Go to the rows and locate the ‘3/4‘ conduit. Find the point where ‘¾’ and ‘8AWG’ intersect. That is the number of 8AWG wires that fit in a ¾ tube.

4). Find The Fill Capacity Yourself

The tables simplify the process of finding the fill capacity. But you can calculate the fill capacity yourself. Figure out the number of wires you want to use and calculate their total diameter. If the total diameter of the wires falls below the maximum fill capacity of the tube, you can use those wires in the pipe.

The NEC will tell you everything you need to know, including the diameter of each wire, the diameter of each conduit type, and the fill capacity.

So long as the total diameter of the wires is less than the conduit’s maximum fill, you don’t have to worry.

What Does NEC Say About It?

The NEC will show you the cross-section area of various cable and wire types. But your primary focus is the specifications they have provided regarding the maximum fill of a conduit. Chapter 9 of the NEC expects one wire to only fill 53 percent of the conduit.

If you have two wires, they should only fill 31 percent of the raceway. With more than two wires, you can’t use more than 40 percent of the conduit’s space.

Things To Consider While Determining How Many Wires Fit In ¾ Conduit

Selecting the correct number of wires for ¾ conduits is a painstaking process that requires the consumer to consider the following factors:

1). Does Conduit Type (PVC, EMT, Flex) Make A Difference?

Conduits are wide-ranging. Each type has unique attributes that fit a particular purpose. For instance:

- EMT – These rigid metal conduits have a metallic construction that allows contractors to use them in ground connections. You can join multiple EMT conduits with couplings to cross long distances. The thin-walled tubes make frequent appearances in residential projects.

- PVC – PVC is one of the most popular options on the market. The tubing looks like an ordinary PVC water pipe. You can buy thinned-walled schedule 40 PVC that appears in underground installations or thick-walled schedule 80 PVC that contractors install in high-traffic areas. Unlike EMTs, you can’t use PVC conduits for grounding. More importantly, they have thicker walls, which translates into fewer wires.

- FMC – As the name suggests, flexible metal conduits are more flexible than metal or PVC. You can guide them around obstacles and inconvenient angles with ease.

The application will influence your conduit of choice. EMT is a stark example. You can use the pipe in projects that require grounding. On the other hand, you can cut FMC conduits into short tubes to accommodate short wiring runs.

But what about the number of wires they can hold? The NEC’s tables show the conduit size and type, proving that it matters. However, if you look at the table below, you can see that the difference is slight.

| Wire Gauge | EMT | PVC | IMC |

| 14 | 22 | 21 | 24 |

| 12 | 16 | 15 | 17 |

| 10 | 10 | 9 | 11 |

| 8 | 6 | 5 | 6 |

| 6 | 4 | 4 | 4 |

| 4 | 2 | 2 | 3 |

| 3 | 1 | 1 | 2 |

| 2 | 1 | 1 | 1 |

| 1 | 1 | 1 | 1 |

| 1/0 | 1 | 1 | 1 |

| 2/0 | 1 | 1 | 1 |

| 3/0 | 1 | 1 | 1 |

| 4/0 | 1 | 1 | 1 |

| 250 | 0 | 0 | 0 |

| 300 | 0 | 0 | 0 |

| 350 | 0 | 0 | 0 |

| 400 | 0 | 0 | 0 |

| 500 | 0 | 0 | 0 |

For instance, ¾ EMT can accommodate 22 14AWG wires. But if you switch to ¾ PVC, it will house 21 wires. You can fit 16 12AWG lines in ¾ EMT and 15 12AWG lines in ¾ PVC. What does this mean? The conduit type matters, but it is not vital.

You don’t select the conduit type based on the number of wires it can handle. You start by matching the conduit type to the application. And then, you calculate the number of wires it can take. There is little point in selecting a conduit that accommodates many wires when it can’t survive the rugged conditions in your setting.

2). Does Wire Type (THHN, THWN, TFFN) Make A Difference?

Wires come in various types. The differences between those wire types matter. For instance:

- NM – Nonmetallic cable, also known as Romex, appears in most homes. It has a plastic sheath surrounding two or more conductors. Running NM wires through a conduit is difficult. As such, the fewer NM wires you must pull through a conduit, the better.

- UF – You can bury underground feeder cables directly without running them through a conduit. Unlike their NM counterparts, each wire in a UF cable has a solid plastic sheath. UF cables are expensive, and people rarely run them through a conduit. There’s no need. Even if you want to use a conduit, the task is quite challenging. Fishing UF cables through a ¾ pipe is not easy. Naturally, the more UF cables you have on hand, the more difficult it becomes to use a conduit.

- THHN/THWN – These wires consist of a single conductor as opposed to multiple conductors in a sheath. You protect this single conductor with a conduit. If you want to use a conduit, THHN is the best option, at least in comparison to NM. You can use NM cables in conduits, but the practice is discouraged because of the challenges it attracts.

The wire type can influence the conduit you select. However, it is unlikely to impact the number of wires you will run through the conduit. After all, the cross-section is the same. It has not changed.

3). Does The Material Make A Difference?

Like the wire type, the material of the wire cannot directly influence the number of lines running through the conduit. Instead, it will affect the ease with which you fish the wires through the conduit.

Copper is often touted as the best material on the market because it has superior conductivity and durability. But aluminum is cheaper. More importantly, it is lighter and easier to install. You can probably pull one wire through a conduit without accounting for the material.

But if you intend to run multiple conductors through the same tube, you should give the material serious thought. Fishing multiple copper lines through a pipe is not easy.

4). Does The Gauge Matter?

The gauge is the primary consideration. The gauge shows you the thickness of the wire, and thicker lines will occupy more space than their thinner counterparts. In other words, the greater the gauge, the smaller the number of conductors a conduit can accept.

For instance, you can fit more 12AWG cables in a ¾ conduit than 6AWG cables because 6AWG occupies more room than 12AWG. Every NEC table you check prioritizes the gauge over every other factor.

5). Do The Laws Make A Difference?

The NEC has strict regulations regarding the amount of conduit space you can use. One conductor can use 53 percent of the pipe’s cross-sectional area. Two conductors can use 31 percent. If you have more than two, they can only use 40 percent of the tube’s cross-sectional area.

This is the only significant regulation that matters to your calculations. However, you should check your local code to see whether it agrees with the NEC. The local code takes priority.

Related Post: