Conduits protect wires. You can find them in various types and sizes. Each type brings a unique attribute to the table. Matching the characteristics to the environment allows you to extend a cable’s life by defending it against corrosive substances and destructive elements such as direct sunlight.

But what about threads? Are they important? Why do they matter? This is what you should know:

1). What Are Conduit Threads?

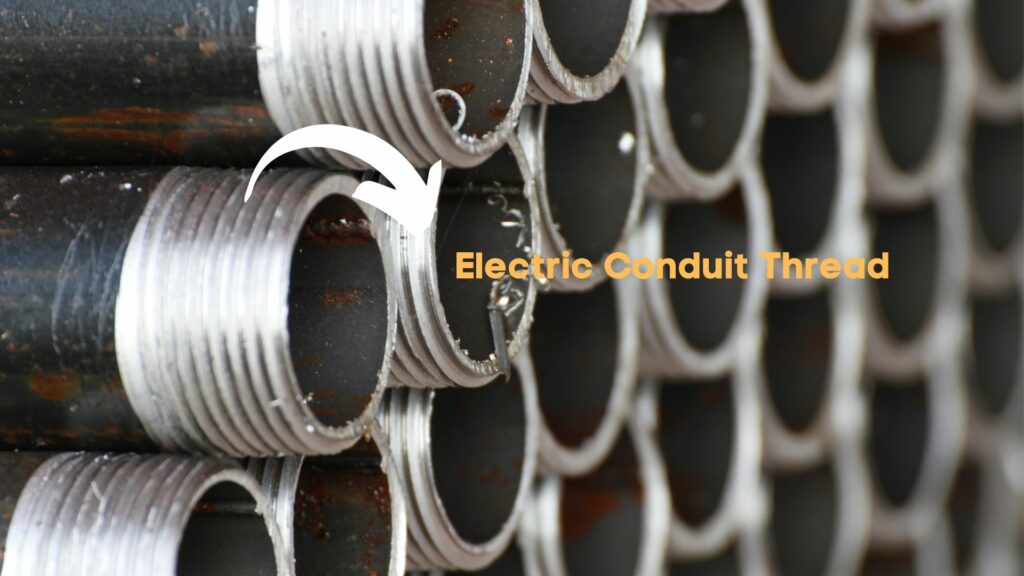

Threads on a pipe are precisely what they sound like. These are internal ridges with a helical structure. They use a rotational movement to bind two pipes. In other words, you will find them on one or both ends of a conduit.

If you’ve ever wondered how a single rigid conduit can cover large distances while making sharp twists and turns along the way, contractors combine multiple pipes. Home Steady associates pipe threads with plumbing applications, which makes sense.

You need tight seals to prevent leaks in a plumbing system. However, some of the pipes you see in a plumbing system can also protect electrical wires.

2). Does The Conduit Type Matter?

Yes, the conduit type makes a difference. Conduits come in various types, including the following:

- Rigid Metal – RMCs are heavy-duty galvanized steel tubes contractors use in outdoor settings. They provide structural support to electrical lines.

- Intermediate Metal – IMCs are similar to rigid metal conduits. However, their walls are thinner. Even though RMCs are stronger, some people favor IMCs because of their lighter build. They are easier to install and manipulate.

- Electrical Metallic – Electrical metallic tubing is a rigid electrical conduit with thin walls and a light build. You can bend it using a conduit bender.

- Electrical Non-Metallic – Electrical non-metallic tubing is flexible. The corrugated plastic conduit resists fire and moisture. You can also bend it if the need arises. Contractors install it within walls. You can’t leave it exposed.

- Flexible Metal – FMCs stand out because of their distinct spiral construction. You can navigate them through and around solid structures. Contractors use them indoors.

- Liquid-Tight Flexible Metal – LFMCs have a flexible build, plastic coating, and sealed fittings that bolster their watertight design. Contractors typically apply them to outdoor AC units.

- Rigid PVC – These conduits are the same plastic pipes that carry water in your plumbing system. They can withstand corrosion.

Consumer base their selection on each conduit type’s strengths and weaknesses. However, you should also take the threading considerations into account, for instance:

- According to the experts at Live About, rigid metal conduits have threads on both ends.

- Intermediate metal conduits are appealing because of their thin construction. However, cable organizer has noted that you can’t thread conduits with thin walls. Contractors use screws and compression fittings to connect them. This doesn’t mean you can’t thread IMCs. Just keep their thin construction in mind before you proceed.

- Galvanized rigid conduits can accommodate threading because of their thick walls. But contractors don’t always thread them.

- You don’t thread EMTs because their walls are too thin.

Electrical Conduit Thread Size

Like the pipes and conduits, you will find threads in various types. The type you select depends on your location and the need at hand:

- NPT (National Pipe Threads)

You will be hard-pressed to find a more popular thread type than this one. The general-purpose threads have a 60-degree thread angle and appear in plumbing and mechanical applications. They can tolerate low-pressure air and liquids.

Because these threads are tapered, they are deepest at the end of the conduit, becoming shallower as you move away. You need to screw the pipe until the taper forces you to stop. But even when you tighten with a wrench, the threads can leave gaps that permit leaks to occur, which is why contractors apply a sealant.

- Dry Seal Thread

NPTF threads are also tapered. Contractors use them when they expect environments with excess heat or pressure to unravel the pipe-sealing compound. You need a wrench to tighten a pipe with NPTF threads. The goal is to join the pipes by slowly crushing the threads. You don’t need sealants.

- BST

You find the British Standard Thread in the UK, Australia, and various Commonwealth nations. The threads are rounded with crests and troughs at 55-degree angles. You can apply BSPP threads (straight) or BSPT threads (tapered seal).

- UNS

You find the Unified Special Thread in the United States and Canada. This is a standard size and design for screws, nuts, and bolts. The crests and troughs have 60-degree angles between them. This is the same as NPT. UNS threads can be coarse, fine, extra-fine, and fixed pitch.

- MIP

MIP is male, while FIP is female. These are pipe fittings. They use NPT threads.

Understanding the different thread types and their attributes is merely the first step. Determining the electrical conduit thread size will involve the following:

- Purpose

Try to match the thread type to the purpose. Some applications will specify the thread type and size. In other cases, the appliance’s origins will inform your decision. For instance, tools from Europe are more likely to favor BSP. Don’t mix and match different thread types. You may damage the threads.

- Gender

Threads are either male or female. The male threads compress into their female counterparts. This will show you how to mix and match threads and conduits.

- Design

Are the threads tapered or straight? This matters because it affects the sealant. For instance, you use gaskets, washers, and o-rings to seal male threads with straight fittings. Tapered fittings use Teflon tape.

- Measurements

When you buy a pipe with threads, measure the inner diameter (female thread) and outer diameter (male thread). Manufacturers don’t necessarily follow standard measurements when crafting thread dimensions. Use a caliper to measure the thread’s dimensions.

- Compatible Pipe Fittings

The applications and environment will determine the pipe fittings. For instance, will the tube run through water or air? Will it run behind a cabinet or out in the open?

The thread chart will make the final decision for you. Once you measure the thread’s dimensions, the thread chart will show you the nominal size. This best materials guide shows a table with different pipe and thread dimensions.

How To Thread Electrical Conduit?

You can buy threaded pipes. Companies like the workshop below can sell you customized pipes with threads if you specify the dimensions. But if you already own conduit pipes, you can thread them yourself using the following steps:

- Use a table-mounted vise to hold the conduit. You want at least four inches of the pipe’s end to protrude from the jaws.

- Make sure the die’s cutting threads are sharp. Replace chipped or dull threads.

- Apply cutting fluid to the die’s internal cutting threads before pushing the inside edge onto the conduit’s end and turning the manual threading ratchet’s handle three or four times (clockwise).

- Take a moment to apply more cutting fluid (behind the front edge of the tapping die) before continuing to thread the conduit by turning the ratchet.

- Flip the ratcheting handle’s directional switch.

- Turn the handle counter-clockwise (¼ turn).

- Add cutting fluid to the conduit (front edge of the tapping die).

- Flip the directional switch clockwise.

- Cut more threads into the conduit until they protrude past the tapping die’s rear edge.

- Flip the directional switch and turn the ratcheting handle counter-clockwise to free the tapping die from the threaded conduit.

- Remove metal shavings from the new threads using a wire brush.

- Use a clean rag to remove the cutting fluid.

This process is relatively straightforward. The cutting tool will do most of the hard work. Just remember to apply the cutting fluid. The lubricant reduces friction, which allows you to make clean cuts. Don’t forget to wear eye protection.