You cannot buy a circuit breaker without knowing the amps of electricity well pump use. The same question will arise if you want to buy a generator. The last thing you want is to underestimate the pump’s power requirements. You could lose everything, not just the generator but the pump itself.

How Many Amps Does A Well Pump Use?

| HP | Watt | Volt | Amps |

| 1 | 745.7W | 110V | 8.47A |

| ½ | 372.85W | 110V | 4.23A |

| 1/3 | 246.081 | 110V | 2.79A |

| 2 | 1491.4 | 110V | 16.94A |

| 3 | 2237.1A | 110V | 25.42A |

| ¾ | 559.27 | 110V | 6.35A |

| 5 | 3728.5 | 110V | 42.36A |

How To Calculate The Amps The Well Pump Use?

Divide the wattage by the voltage. For instance, if the voltage is 110V and the pump has a watt rating of 1400W, divide 1400 by 110. Now, according to the 80% rule, the amperage is 12.72*1.25 which gives you 15.9 amps.

To calculate the number of amps a well pump uses, you should start by determining the wattage. This involves the following:

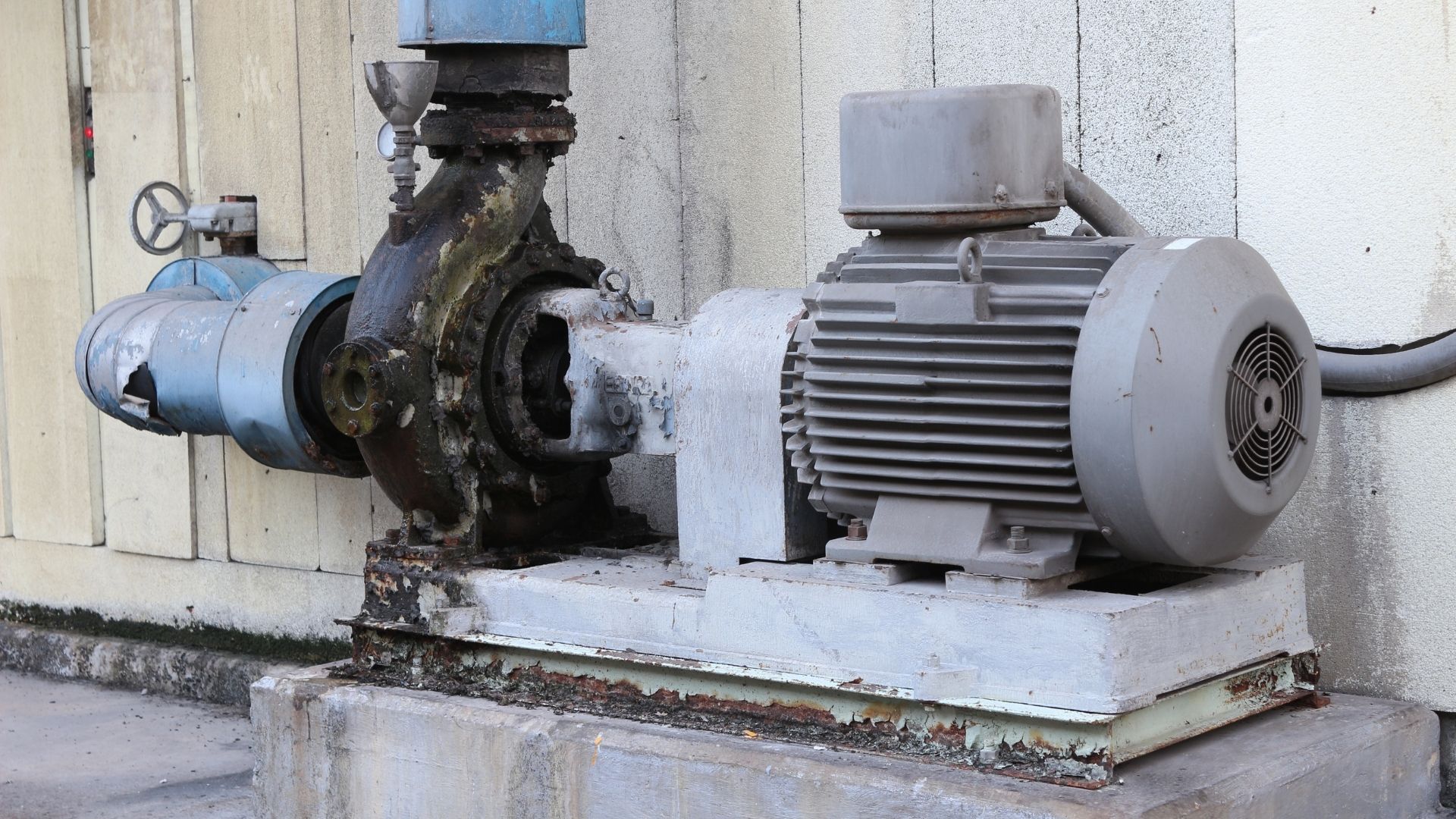

1). Check The Label

Start by checking the label on the pump. Modern pumps provide all the information you need, including horsepower and wattage. Some pumps will include the amp rating. You can only use this method if the pump in question is above ground.

You cannot dig hundreds of feet into the ground to find a submersible pump just to check the label. Even if you could, those labels tend to fade overtime.

2). Check The Control Box

If you have a submersible pump and your contractor already buried it, you can use the control box. Some control boxes have a label on the outside that reveals the pump’s amperage and wattage.

If your control box has this information on the inside, shut the power off and remove the cover.

3). Ask The Manufacturer

Consult a professional. Talk to the contractor that installed the pump. They should know the wattage or amp rating because they need that information to install a circuit breaker or even a generator if you have one.

If they bought the pump on your behalf, the invoice should reveal the rating. You can reach out to the manufacturer directly.

4). Check The Circuit Breaker

The circuit breaker can tell you volumes about the electrical requirements of the well pump. The person who installed the device would have taken the pump’s amp rating into account before adding the circuit breaker. Therefore, determining the breaker’s size can indirectly reveal the pump’s electrical rating.

For instance, a 4.23A breaker works with 0.5hp (or less) pumps. If you have a 16.94A circuit breaker, it works for a 2-3 hp well pump. A 42.36A breaker works with a 5hp well pump.

In the best-case scenario, a well pump’s label will show you the amps it uses. If it doesn’t, you can use the horsepower. There are numerous tables on the internet that show the amp ratings associated with each hp rating.

You can do the same thing for the circuit breaker. Some tables will show you the different breaker sizes and their related well pump watt, amp, and hp ratings.

But if you’re determined to calculate the amps yourself, identifying the wattage is simply the first step. You must also figure out the voltage. Some countries use 110/120V. If you live in Europe, your voltage is probably closer to 240V.

What Factors Should Be Considered While Calculating Amps For Well Pump?

The only thing you need to calculate the amps a well pump uses is the pump’s wattage and the voltage rating of your electrical system. But calculating a well pump’s amp rating is not enough.

You have a bigger problem. If you have kitchen appliances with motors, you know that they use a lot of electricity when they cycle on. Pumps are the same.

1HP pump that technically draws ten amps of electricity. However, when you start it, the pump will draw a whopping 35 amps.

Fortunately, this doesn’t last long. The pump’s electrical draw will double or even triple as it accelerates.

But after five to ten seconds, the power usage will fall to acceptable levels. But that is not a cause for celebration. If the breaker size matches the amperage of the well pump, those 5 – 10 seconds are enough to start a fire and destroy the pump.

Therefore, it is not enough to calculate the number of amps a pump uses during normal operations. You must also consider the starting current. The breaker size should be significantly larger than the pump’s amperage.

Keep in mind that the NEC discourages consumers from using more than 80 percent of a circuit’s capacity. This rule should inform your calculations.

This is why laypeople are better off consulting experts before installing well pumps. A layperson can calculate a pump’s amp rating on their own, especially if they can find the watt rating on the pump’s label.

But a layperson cannot determine the starting amperage unless the pump’s label reveals this information. Find a professional contractor that has experience with well pumps.

They can coordinate with the manufacturer to estimate the starting amperage.

Does Above Ground VS Submersible Well Pump Make A Difference In Amps?

Above ground and submersible well pumps differ from one another. These differences matter because they affect the efficiency of each pump:

Above Ground Pumps

Jet pumps sit above the ground. You can buy single drop or double drop jet-pump systems. Either way, the pump in question uses suction to pull water out of the well.

While you can use jet pumps to operate deep wells, people typically pair them with shallow wells.

Submersible Pumps

Contractors use submersible pumps on wells that exceed 25 feet in depth. While the jet pump sits above the well, the submersible option goes in the well. Submersible pumps must fill with water before they can do their work.

Between the two, submersible pumps are the more efficient option, and you can probably see why. Above-ground pumps are typically larger. This device carries more power.

You can blame this on the fact that they pull water. Additionally, you must prime them before they can work.

Submersible pumps stand out because they push the water up the well instead of pulling it. Their design creates several interesting advantages. First of all, they have fewer mechanical complications.

Secondly, you don’t have to prime them because they never lose prime in the first place. Third, above-ground pumps can develop air pockets that users must remove before utilizing the pump.

You won’t find this problem in a submersible pump. Because of all these attributes, submersible pumps will use fewer amps to deliver more water than an above-ground pump with the same motor.

Of course, that is not a good reason to invest in a submersible pump. You should buy the above-ground option if you have a shallow well. Ultimately, for all their benefits, submersible pumps have one significant problem.

If they develop a fault, you have to remove the entire unit from the well. This can be a costly undertaking. Admittedly, submersible units are durable. They can work reliably for 25 years without servicing. That being said, they can become an inconvenience once a malfunction occurs.

Does Voltage Make A Difference?

The voltage matters to an extent. A 240V pump can run on 120V. However, the low voltage will debilitate the pump’s operations. You can expect much weaker pressure and unreliable operations. A pump’s motor can overheat because of low voltage.

If you check a pump’s label, it will show you the voltage required to run it. You should match that voltage. For instance, if your pump requires 240V, give it 240V.

There’s a reason why manufacturers include a pump’s voltage in the manual. It matters. You can determine a pump’s voltage by removing the control box cover and testing the pump with a voltmeter.

How Many Amps Does 220, 240V Well Pump Use?

220V well pump draw

| HP | Volt | Amp |

| 1 | 220V | 4.23A |

| 1/2 | 220V | 2.11A |

| 1/3 | 220V | 1.39A |

| 2 | 220V | 8.47A |

| 3 | 220V | 12.71A |

| 3/4 | 220V | 3.17A |

| 5 | 220V | 21.18A |

240V well pump draw

| HP | Volt | Amp |

| 1 | 240V | 3.88A |

| 1/2 | 240V | 1.94A |

| 1/3 | 240V | 1.28A |

| 2 | 240V | 7.76A |

| 3 | 240V | 11.65A |

| 3/4 | 240V | 2.91A |

| 5 | 240V | 19.41A |

If you have a 2,200W unit, dividing 2,200 by 220V gives you ten amps. On the other hand, dividing 2,200 by 240 gives you 9.16 amps, which is more or less ten amps. If your electrical system uses 110V, dividing 2,200 by 110V gives you 20 amps.

Therefore, a higher voltage produces lower amps, and a lower voltage delivers higher amps.

Advantage of Knowing Well Pump Amps

You can select the right circuit breaker if you know a pump’s amp rating. Small-sized circuit breakers have thin wires that are more likely to catch fire if you expose them to powerful pumps that use a lot of electricity.

If you know the amp rating, you can prevent unnecessary fires that start because of overwhelmed circuit breakers. You can also prevent the pump from burning out.

Related post: