Do you need a conduit to wire your sub-panel? This guide will show you the correct conduit size to use for the sub-panel.

What Size Conduit For 60, 70, 100, 125, 150, and 200 Amp Subpanel?

| 60 | 1 Inch |

| 70 | 1 Inch |

| 100 | 1 ¼ Inch |

| 125 | 1 ¼ Inch |

| 150 | 1 ¼ Inch |

| 200 | 1 ½ Inch |

These are the minimum conduit sizes for 60, 70, 100, 125, 150, and 200A subpanels. But you can’t take those figures at face value. Identifying the correct conduit size for 60, 70, 100, 125, and 200A subpanels is not quite as easy as you think. Consider the following:

1). Conduit

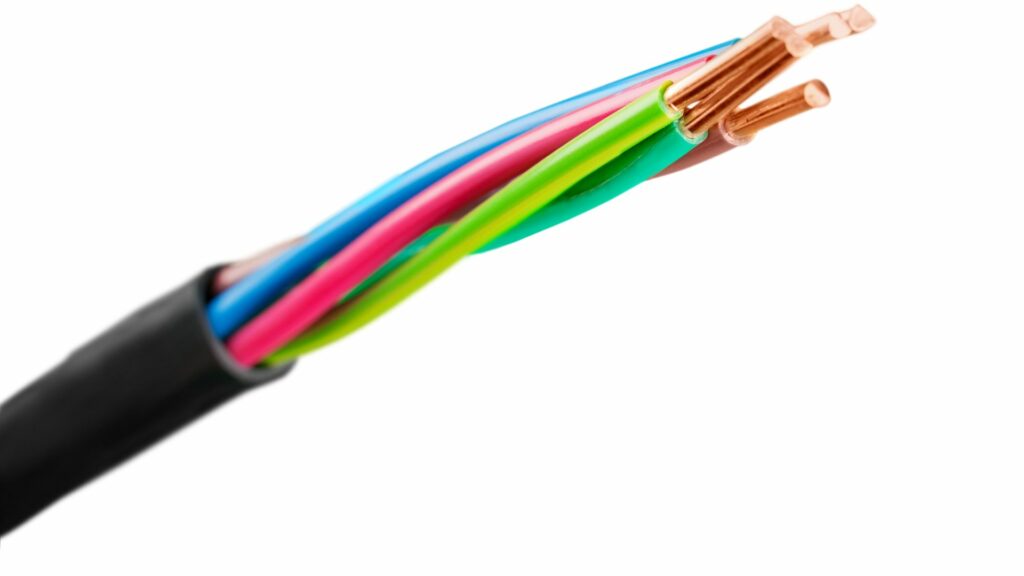

A conduit is a pipe. The material will vary depending on the purpose you have in mind. The most crucial factor is the conduit fill (the amount of cross-sectional area a cable can occupy). The NEC recommends conduit fills for each wire size.

You can’t afford to ignore these recommendations. First, inspectors will penalize you. Secondly, electricity generates heat when it passes through a conductor. Pulling a conductor through a tube limits ventilation, allowing the heat to accumulate. As such, crowding a conduit can lead to overheating.

2). Number Of Wires

The most important consideration where the conduit size is concerned is the number of wires. You can pull the average conductor through most of the conduit sizes the market offers because electrical conductors are pretty thin.

The conduit fill comes into play when you need to pull multiple wires through the same conduit. The conduit size and fill will show you the number of wires the pipe can safely accommodate.

3). Conduit Size

You won’t find a straightforward answer to this question because the answer depends on the number of wires you want to pull through the conductor. For instance, if you’re going to install a 60A subpanel, consider the fact that contractors typically pair 60A panels and breakers with 4AWG wire.

According to the NEC, you can pull one 4AWG conductor through a ½ EMT pipe. Does this mean ½ EMT is the correct conduit size for a 60A subpanel?

Not necessarily. How many wires does your project require? Do you intend to hide them all inside a conduit? Clearly, a ½ EMT conduit is insufficient for multiple 4AWG wires. You must upgrade to a bigger conduit.

This same rationale will apply to the other amp ratings. For instance, you need a 2/0AWG copper wire to accommodate the electrical needs of a 200-amp panel. Based on the NEC’s tables, you can’t fit even one 2/0AWG wire in a ½ EMT conduit.

You need ¾ EMT to house one 2/0AWG. Three 2/0AWG wires require 1 ¼ IMC to stand the test of time. But what if you need six 2/0AWG lines? Once again, you must opt for a larger pipe. The wire and conduit materials will also influence your decision. As you can see, buying tubing for a subpanel is not easy.

Talk to a professional. They have the experience to account for all the critical variables before choosing a conduit size for your sub-panel.

How To Determine The Correct Conduit Size For Subpanel?

- Get an NEC book. You need a table that shows the conduit and wire sizes. You can find these tables on the internet if you don’t have an NEC book.

- Find the appropriate conduit size, type, and wire gauge in the table, and identify the cell where they intersect to determine the appropriate number of lines that can fit in the conduit. Select a conduit size whose recommended wires exceed the number you want to use.

- If you have a specific gauge in mind and you know the number of cables you need, use the equation Syston cable has published to calculate the cross-sectional area. Get the total cross-sectional area of all the cables you need.

The primary objective of these steps is to find the cross-sectional area and conduit fill. The conduit size should always exceed the total cross-sectional area of all the wires your sub-panel requires. Don’t forget these three variables:

1). NEC rules

The NEC’s rules have assigned a maximum fill of 53 percent for one wire, 31 percent for two wires, and 40 percent for three or more wires. The fill, in this case, refers to the amount of space in the conduit the wires can occupy.

2). Conduit Material

You can find conduits in various types. EMT conduits are rigid metal pipes with thin walls. They can provide a grounding connection to metal enclosures. PVC conduits are the most popular of the bunch. Contractors use plastic tubes for underground installations.

FCM conduits are highly flexible, which is why people use them to maneuver wires around obstacles. Every NEC table you consult will account for the conduit type.

3). Wire Type

Like the conduit type, every NEC table mentions the wire type. Factors such as the setting and temperature will influence the wire type. For instance, you use THHW for wet locations (167 degrees F) and dry locations (90 degrees C). With THHN, the rated temperature for dry and damp areas is 194 degrees F.

Does Subpanel Wire Even Need To Be In Conduit?

Individual THHN conductors require a conduit. Conduits are defensive tools that protect wires from harm. Therefore, lines that travel through locations with destructive and corrosive elements need protective tubing.

This is especially true for exposed conductors. You have exceptions such as direct burial wire, which contractors can install underground without using a conduit. This is also true for armored lines with insulation strong enough to withstand most threats.

Your contractor will make the final decision. Conduits are annoying. Not only do they increase your expenses, but pulling lines through a pipe is challenging. A contractor will only recommend a conduit for the subpanel if these pipes are absolutely necessary.

Related post: