1AWG has a diameter of 0.2893 inches (7.348mm), a cross-section of 42.4mm2, and a current-carrying capacity of 130A at 75 degrees C. All those attributes matter because they tell you what the line can handle. For instance:

- AWG

‘1’ is AWG, which stands for ‘American Wire Gauge.’ Despite its name, many countries outside North America use AWG because of its convenience. The unit of measurement ranges between 0000 and 40AWG. The higher you go, the larger the number, and the smaller the wire becomes.

In other words, 1AWG is very thick, and 40AWG is really small. Common sense will tell you to assume the opposite. But in this case, a smaller number points to a bigger wire.

- MM2

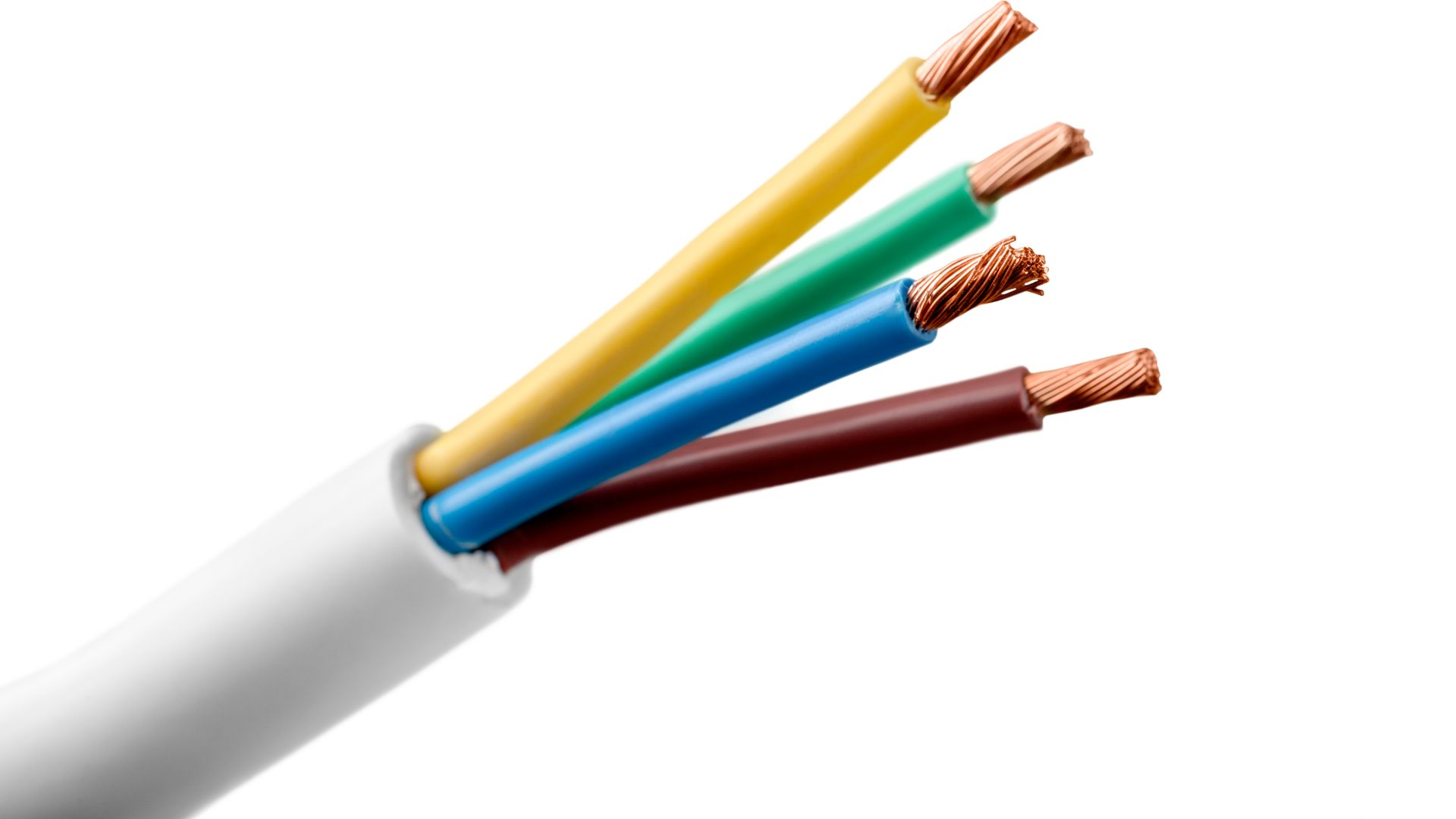

People confuse the diameter and cross-section because you measure one in MM (Diameter) while the other uses MM2 (Cross-Section). But what is the difference? Get a cable and cut it across the width.

Because the cable is cylindrical, the open end should look like a circle. The diameter is obvious. It is basically the diameter of that circle. The area is the cross-section, but you express it in mm2.

A larger cross-sectional area equates to lower resistance per foot. The bigger the cross-section, the more current a conductor will carry. 1AWG has a larger cross-section than all the wire sizes below (2AWG – 40AWG). Therefore, it carries more electricity than all of them.

- MM

Gauge (AWG) goes down as the diameter in MM increases. The metric gauge scale is different. The gauge is ten times the MM (diameter) in the metric gauge scale.

Most laypeople don’t need to know the MM, MM2, and inches of a 1AWG wire. The AWG is enough to tell you the amps. However, you can use any of these units to find the other. For instance, if you know the MM2, you can find the gauge and amps using this table

| Copper | Aluminum | |||||

| Wire Gauge Size | 60˚C TW, UF | 75˚C THW, THHW, THWN, USE, XHHW, ZW | 90˚C THWN-2, THHN, XHHW-2, USE-2 | 60˚C | 75˚C THW, THWN, SE, USE, XHHW | 90˚C XHHW-2, THHN, THWN-2 |

| 1 AWG | 110 A | 130 A | 150 A | 85 A | 100 A | 115A |

But most people can do without the MM, MM2, and inches. They only matter to engineers who must perform complex calculations requiring precise measurements.

How Do You Find 1 Gauge Wire Amps?

Go to the NEC and find the wire size chart. The chart has a column showing the different gauges. The rows reveal the ampacities, which change depending on the temperature rating, material, and wire types.

Find ‘1AWG’ in the wire size column and look at the corresponding rows to identify the ampacity. You can confirm with an electrician if you have doubts about the NEC’s information. Contractors in most states use the NEC to make electrical decisions.

However, if your local code deviates from the NEC’s rulings, an electrician can review it to determine what it has to say about 1AWG wires. You don’t have to obey the NEC. The National Electric Code is a series of guidelines, not a law.

But the local code governs your actions. Don’t exceed the ampacity the local code has recommended for your 1-gauge wires.

What Are The Uses Of 1 Gauge Wiring?

Most people can’t wrap their heads around an electrical cable this thick. You won’t find it in your outlets and switches. Few appliances in residential settings use 130 amps. People use 1/0 gauge cables in batteries. The size runs incredibly powerful applications. In fact, it can handle 300 amps if you limit the length to eight feet.

But 1/0 is one size larger than 1AWG. 1/0 carries 150 amps, which puts the gauge within the same range as 1AWG. In other words, 1AWG can also run heavy-duty battery-related applications. Additionally, it can work as a welding cable.

If you want to know what 1AWG can do for you in a residential setting, you find 2-gauge wiring in service panels and sub panels. 1-gauge cables can perform a similar role.

Is 1 Gauge Wire Expensive?

The price tag increases with the gauge. The thickest wires are the most expensive. So naturally, 1AWG will cost you more than every smaller gauge. Depending on the brand, you may spend $5 per foot.

Some brands are cheaper. But you can’t always trust them. Don’t take chances on inexpensive 1AWG cables without first investigating the manufacturer’s reputation. Keep in mind that 1-gauge wires can transmit 130 amps, which is a lot of power. A low-quality 1AWG cable is a fire and electrocution hazard.

Does The Temperature Rating Change 1AWG Wire Amps?

Yes, the temperature rating changes the amps. A 1-gauge line carries 110A at 60 degrees C, 130 A at 75 degrees C, and 150A at 90 degrees C. Conductors oppose the flow of electricity. When you increase the temperature, the resistance will also rise.

And unfortunately, a high resistance boosts the heat a conductor generates when you connect a load. Additionally, the voltage drop will also spike, compromising the volume of electricity reaching your application.

What does this mean? A high temperature can lower a cable’s ampacity. Contractors will limit the load size based on the ambient temperature and setting. For instance, you can’t afford to overwhelm a wire hidden behind a wall because the ventilation is poor. The heat has nowhere to go.

A high-temperature rating solves this problem. Some wires are designed to withstand more heat than others. The more heat a wire can tolerate, the more amps it can carry without overheating. Logic will tell you to prioritize 1-gauge wiring with the highest temperature rating to take advantage of the elevated ampacity.

But the price tag will increase with the temperature rating. Therefore, you should consult a professional. Let them assess the environment. If you want to bury the 1-gauge wire, the contractor will consider the possibility of using an armored cable or running the line through a conduit.

Does The Length Change 1-Gauge Wire Amps?

For Copper Wire,

Single Phase

| Voltage | Amp | Voltage Drop | Max Distance |

| 120 V | 110 | 3% | 122 ft |

| 240 V | 110 | 3% | 244 ft |

| 480 V | 110 | 3% | 489 ft |

Three Phase

| Voltage | Amp | Voltage Drop | Max Distance |

| 120 | 110 | 3% | 141 ft |

| 240 | 110 | 3% | 282 ft |

| 480 | 110 | 3% | 564 ft |

A wire’s relationship with the length is similar to its relationship with the temperature. A longer wire equates to a higher resistance. If a conductor naturally opposes the flow of current, the more of that conductor you have, the more opposition the current will encounter.

The length makes the voltage drop a threat to your application. Overheating is just as likely. 1AWG is one of the thickest gauges on the market. But it can still overheat if you make it long enough while attaching a load that exceeds the conductor’s amp rating.

You can prevent overheating by lowering the load size, reducing the length, or increasing the wire size.

Does The Material Affect 1 Gauge Wire Amps (Copper VS Aluminum)

The material will either increase or lower the amperage. This is because copper is more conductive than aluminum. It has a higher current-carrying capacity. Therefore, a 1AWG copper line carries more amps than its aluminum counterpart.

Aluminum gained prominence in the 1960s because of a copper shortage. But it fell out of favor in some circles because of its inferiority. At the time, aluminum was too soft, and its penchant for thermal expansion was too great.

It would expand while transmitting electricity because of the heat and then contract when it cooled, compromising its connection to the terminal. Today, aluminum is more reliable. The key is to match the gauge to the need.

You need a higher gauge to replace a 1-gauge copper wire with aluminum. People use aluminum because the material is budget-friendly.

Does The Design Affect 1-Gauge Wire Amps? (Stranded VS Solid Wire)

Technically, the design influences the current-carrying capacity. But practically, it doesn’t matter. WPPI Energy sees solid conductors in smaller gauges. Wires larger than 6AWG are stranded.

This makes sense because the thickest lines are also the stiffest. They are the least flexible, which is why contractors hate pulling them through conduits. Stranded wires differ from solid conductors because of their flexibility. They consist of smaller strands.

Solid wires carry more electricity because they have a smaller surface area. Stranded wires are compromised by the air gaps in their structure. But the difference in current-carrying capacity between solid and stranded cables is unlikely to influence your decisions.