Most contractors would rather avoid conduits because pulling a cable through one is challenging. The guide below will tell you whether or not you should make an exception for 8-gauge wiring.

Does 8 Gauge Wire Need To Be In Conduit?

1). You Determine The Necessity Of a Conduit By Looking At The Setting.

A conduit protects wires from harm. Contractors tolerate pipes despite their challenges because they enhance a conductor’s longevity.

You don’t pull 8-gauge wires through a conduit because that particular wire size requires protective tubing. You pull 8-gauge lines through a conduit because they won’t survive the harsh elements in the environment without protection.

Laypeople associate conduits with outdoor installations. But this Science Direct paper has seen conduits in office projects whose wires must run through concrete floors and brick walls.

2). Grounding

What if environmental conditions are not dangerous enough to necessitate conduits? You can still pull 8-gauge wiring through a pipe if your project requires grounding. The Steel Tube Institute (Glenview, IL) published a study that emphasized the critical role steel conduits can play as grounding instruments. Conduits can serve a multitude of functions.

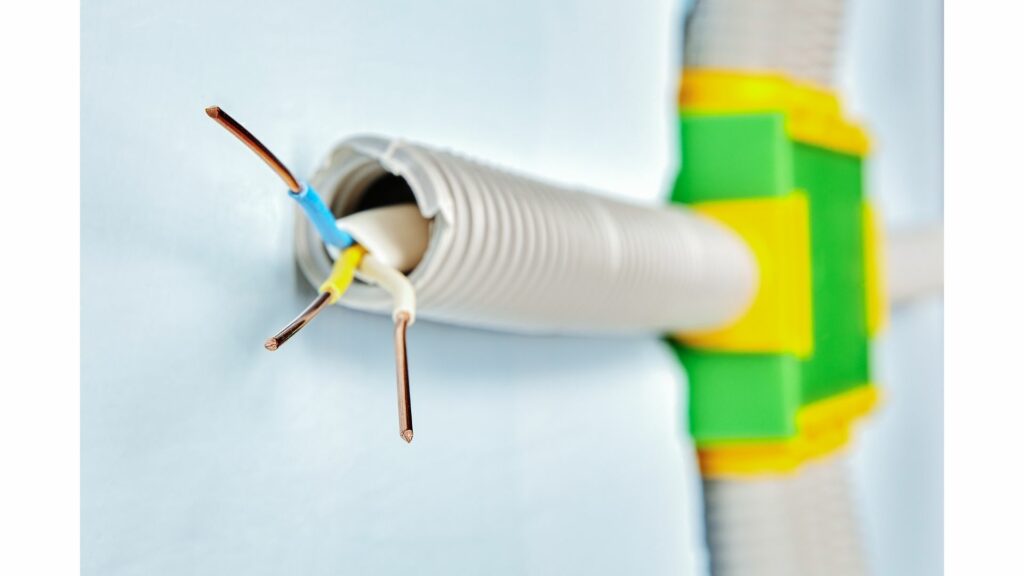

3). THHN Lines Require A Conduit

What type of 8-gauge wire do you have on hand? THHN (Thermoplastic High Heat Resistant Nylon) lines require a conduit because the conductors use insulation for protection, which is insufficient.

THHN appears in many residential and commercial applications. It can even withstand underground installations. But you need the appropriate pipe to repel threats like moisture, pressure, and pests.

According to the spruce, pulling THHN through a tube is less of a challenge, especially in comparison to Romex. Romex has a sheath that complicates matters. You can pull 8-gauge Romex through a conduit if you want.

But the practice is not mandatory. The sheath consumes space. You’re more likely to crowd the tube.

4). Individual Conductors Must Run Through A Conduit

If you’re talking about individual conductors, you must run them through a conduit. The NEC doesn’t give you a choice here. Your project won’t pass inspection if the conductors are exposed.

These are the number of 8AWG wires an EMT conduit can withstand at various sizes. These figures will change in response to the wire type and conduit type.

What Size Conduit For 8, 8/2, 8/3, 8/4 AWG Wire?

| Conduit Size | 8AWG | 8/2 AWG | 8/3 AWG | 8/4 AWG |

| 1/2 | 3 | 3 | 3 | 3 |

| 3/4 | 6 | 6 | 6 | 6 |

| 1 | 9 | 9 | 9 | 9 |

| 1 1/4 | 16 | 16 | 16 | 16 |

| 1 1/2 | 22 | 22 | 22 | 22 |

| 2 | 36 | 36 | 36 | 36 |

| 2 1/2 | 64 | 64 | 64 | 64 |

| 3 | 96 | 96 | 96 | 96 |

| 3 1/2 | 126 | 126 | 126 | 126 |

| 4 | 161 | 161 | 161 | 161 |

How To Determine The Correct Conduit Size For 8-Gauge Wire?

The gauge tells you the thickness. The smaller the number, the thicker the cable. For instance, 1AWG is thicker than 10AWG. The thickness tells you the number of amps the conductors can carry.

Once you know the gauge, you can compare it to the information in an NEC wire size/ampacity chart to identify the corresponding ampacity. The gauge cannot tell you whether or not a cable requires a conduit.

Consider this Western Tube table. It shows the number of wires each conduit type and size can accommodate. You determine the correct number of wires to add to a conduit by identifying the gauge.

The top section shows wire sizes starting at 14AWG and ascending. The gauge tells you the number of lines the pipe can safely withstand. It doesn’t tell you whether or not you can run those lines through the conduit. This is why conduit/wire size tables mention all the prominent wire sizes, including 8AWG.

Things To Consider Before Using 8 Gauge Wire In Conduit

Best Conduit Type For 8-Gauge Wire

The type depends on the purpose you have in mind. Different conduit types offer different features and attributes. Electrical metallic tubing is common in residential settings. Contractors use rigid metal conduits to create ground connections.

Because PVC is plastic, you can’t use it for grounding. Contractors install it underground. It can also defend 8-gauge wiring in wet locations. You can buy schedule 40 or schedule 80 PVC, depending on the thickness you require.

FCM is suitable for short runs. The conduit’s flexibility is its biggest draw. If you want to maneuver 8-gauge wires around sharp bends, FCM is the conduit to use. There is no such thing as the best conduit type for 8-gauge wiring. Your needs will dictate the type.

You can avoid conduits altogether if you select a wire type with a sheath capable of withstanding harsh elements.

Number Of Wires In Conduit

You identify the number of wires a conduit can accept by determining the fill capacity. Each conduit type and size can accommodate a specific number of wires. That number depends on the gauge.

For instance, you can fit three 8-gauge wires in a ½ EMT conduit. If you have an NEC book, it has similar tables. Use them to identify the correct number of 8-gauge lines for the conduit type and size you’ve selected.

Type of Wire

The type of wire will make all the difference. For instance, armored cabling can survive without a conduit. The jacket is robust and more than capable of repelling threats. UF feeder cable is another solid option.

You can bury it directly. The NEC doesn’t mandate the use of protective tubing for 8-gauge Romex. But you can run the line through a conduit if the elements threaten the wire’s integrity. THHN is the least challenging to pull through a pipe.

You can run armored and even UF feeder cables through a conduit. But you need larger sizes than what THHN uses because the thick jackets occupy more space. This is why a wire’s dimensions are so important.

Even when the gauge is the same, the diameter and cross-section of the different wire types may vary slightly. A licensed contractor will take those dimensions into account when identifying a suitable wire size. Consult an expert before you choose a wire type and conduit size.

You can fit more wires in a conduit when you use types like THHN that don’t have a sheath. But if your application calls for a different wire type, an electrician can point you toward the correct conduit.

Should You Strip 8-Gauge Wiring?

It depends on the type of cable. Technically speaking, you can strip any cable. This will make it easier to pull the conductors through a conduit. You see this in Romex. The NEC doesn’t mandate the use of conduits for Romex.

Romex has a sheath. Not only is it more difficult to pull 8-gauge Romex through a pipe, but the line is more likely to overheat. Many contractors solve this problem by stripping the Romex. You can do the same for other cables.

In fact, this allows you to pull more lines through the tubing. You can also use smaller pipes. However, many electricians frown upon this practice. First of all, it limits the wire’s applications. Secondly, the practice removes vital markings that reveal the wire type, insulation, dimensions, etc.

You may pair the cable with the wrong application in the future because you’ve forgotten the size. If you’re tempted to strip your cable, just use THHN instead.

Solid VS Stranded

Conduits that accommodate stranded wires will also accept their solid counterparts. However, stranded cables are easier to handle. They are more convenient to fish through challenging conduits.

But solid cables are superior conductors. You should weigh the pros and cons before making a decision. Don’t allow a stranded cable’s convenience to influence your decision. Choose the option that serves the application best.